Asahi Variable Durometer Tube makes better blood vessel trackability your catheter possible.

Our innovative process minimizes labor and makes streamlines your catheter manufacturing.

Are you in trouble with a manually assembled tube?

Poor blood vessel trackability can occur due to sudden changes in stiffness at welded points of the manually assembled tube.

Furthermore, this can induce radial compression of the lumen when in a bend, affecting device deliverability in tortuous anatomies.

Manual manufacturing can significantly increase the complexity of the catheter's manufacturing process.

Our innovative process eliminates the traditional manual approach.

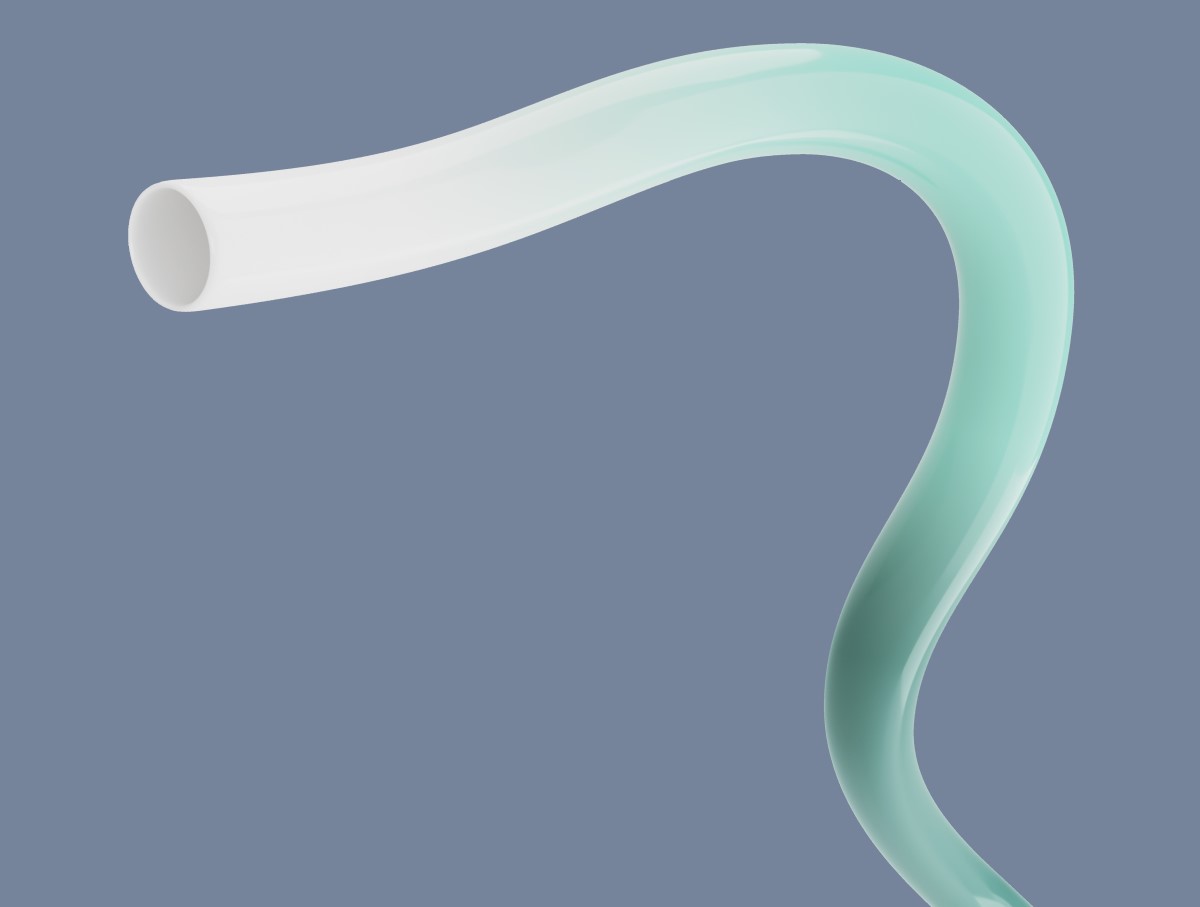

The continuous extrusion process realizes excellent blood vessel trackability due to its linear transition from a soft tip to the hard proximal end.

A streamlined process for your catheter manufacturing, which minimizes labor, can be more easily validated and is less susceptible to lot-to-lot variations.

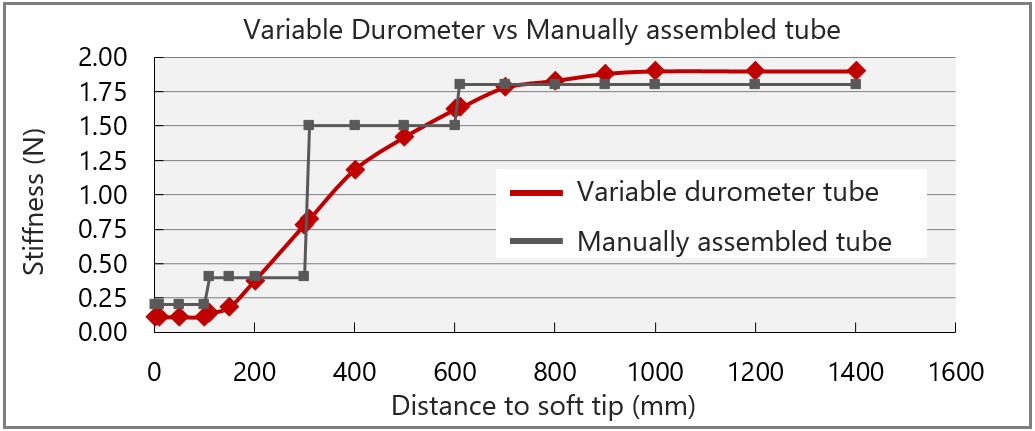

What is the difference between Variable Durometer and Manually Assembled Tube?

Here is a comparison Graph showing how stiffness changes from a delicately soft tip to a hard proximal end.

Here is a comparison of its increased bending smoothness.

How we manufacture it?

Our continuous extrusion process with switching die realizes a smooth transition of resin and minimizes labor.

Why Asahi?

44+ years experience and dedicated engineering

In-house ISO certified production facilities